|

University Park PA (SPX) Aug 21, 2007 A variety of end products including jet fuel, gasoline, carbon anodes and heating oil may be possible using existing refineries and combinations of coal and refinery by-products, according to a team of Penn State researchers. "One idea is based on the coal-to-jet fuel work that we have been doing for a long time," says Caroline E. Burgess Clifford, research associate at Penn State's Energy Institute. "Our aim is to integrate the processes and products into existing refinery structures and streams." The coal-to-jet fuel work is in the pilot plant stage, but along with the jet fuel, the process produces other hydrocarbon products. For every eight barrels of a Jet A equivalent, the process produces a half barrel of fuel oil, one barrel of diesel and a half barrel of gasoline. "We need to be sure that these components fit into the refinery stream that they are close enough in composition to be mixed with the components coming from crude oil," says Clifford. So far, the researchers, including Harold Schobert, professor of fuel sciences; Maria M. Escallon and Utaiporn Suryapraphadilok, graduate students; Gareth D. Mitchell, Omer Gul, Josefa M. Griffith and Parvana Gafarova, research associates, Energy Institute, characterize the gasoline and fuel oil as fitting within the standard crude oil refinery stream. The diesel fuel is different from standard diesel fuel. Other participants in this project tested the products in real units, including Andre Boehman, professor of fuel science and his group who tested the gasoline and diesel in engines; Bruce Miller, senior research associate and his group who tested the fuel oil in a pilot scale boiler; and Chunshan Song, director of the Energy Institute and professor of fuel science and his group who did related catalyst research. "The produced diesel can be blended with the petroleum diesel without changing the fuel properties significantly," says Clifford. "It has not been shown to be bad or have bad effects, it is just different. We are also examining the produced jet fuel to see if it could be used as a diesel fuel, as the jet fuel has undergone extensively more processing than the other products." The pilot plant demonstration process uses coal tar and refinery solvent blended, cleaned and treated to produce the various fractions. In another process aimed at producing jet fuel, they mix raw, clean coal with decant oil - the liquid found at the bottom after catalytic cracking - and then co-coke. Fuel-grade coke, which is a standard fuel in the steel industry, sells for about $20 a ton. This co-coking process aims to produce coke or carbon of much higher quality usable in manufacturing carbon anodes for a variety of uses. The coke used in these anodes is a much higher value than fuel coke. "So far the process has produced really good carbon, but it contains too many residual minerals for anode use," says Clifford. "The liquid component does include jet fuel, but the liquid products are very heavy in fuel oil." The researchers report at the American Chemical Society meeting today (Aug. 20), in Boston that future work will strive to reduce impurities in the solid carbon product. Researchers will also investigate either fractionating the fuel oil component or improving the liquid yield. Another approach to achieving liquid fuels from coal is to extract the liquids from coal using refinery liquid. This method uses light cycle oil to extract the liquid components of coal and then the liquid portion, without separation, travels on through the refinery hydrotreater. In initial bench testing, this method produced a 50 percent yield of liquids. When processed in a multistage reactor, 70 percent extraction took place. The researchers are continuing this work to reduce the amount of light cycle oil necessary, develop a method to separate liquids and solids, and scale up the process.

The U.S. Department of Energy funded the jet fuel research Community Email This Article Comment On This Article Related Links Penn State Powering The World in the 21st Century at Energy-Daily.com

Moscow (RIA Novosti) Aug 21, 2007

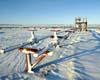

Moscow (RIA Novosti) Aug 21, 2007Russia's Natural Resources Ministry is offering 93 new deposits for prospecting, including fields in East and West Siberia, the ministry's press office said Monday. "The ministry has approved new lists of deposits offered for geological prospecting in 2007 at the expense of natural resources companies," the ministry said in a statement. |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2007 - SpaceDaily.AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |